Fogged up glasses, windscreens and bathroom mirrors may be a thing of the past.

Researchers have invented a new, permanent, multi-purpose coating technology that will prevent your spectacles, car windscreen or bathroom mirror fogging up ever again.

The coating, called XeroCoat, also cuts out unwanted reflections from glass, letting more light through. Making it ideal for spectacles and improving the performance of solar cells and glasshouses.

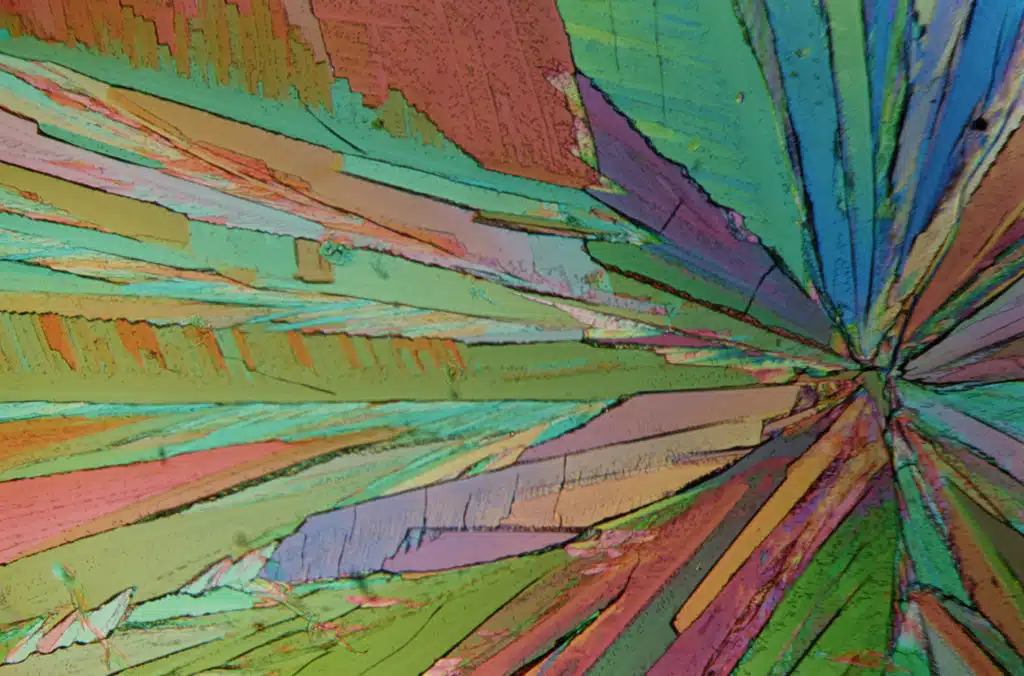

University of Queensland physicists Michael Harvey and Paul Meredith developed this technology based upon thin films of nano-porous silica; this means that “the coating is a layer of glass full of tiny invisible bubbles, just like the foam on beer,” said Mr Harvey. “Because it’s made of glass it’s as hard as glass,” he said, giving the added benefit of a hard coating on items to prevent or reduce scratching.

The whole production process is extremely simple, very low-cost and environmentally friendly. Queensland’s Sustainable Energy Innovation Fund, administered by the Environmental Protection Agency, recently awarded the team a grant to further develop the new coating. Their support will allow trials of this technology to improve the efficiency of solar cells, with the first improved prototypes expected by January 2005.

Dr Meredith said existing technologies for applying anti-reflection coatings were all too expensive for the wide areas required for solar collector surfaces. “This innovation is set to revolutionise the use of solar energy by making it cheaper and more effective,” he said.

Mr Harvey said that the new coating can be applied to many surfaces, including glass and plastics, and so permanently prevent these items fogging up. He is now developing this anti-fogging, anti-reflection and scratch resistant coating for products such as spectacles, sunglasses, windscreens and bathroom mirrors.

The University of Queensland’s commercialisation arm, UniQuest, has formed a company, XeroCoat Pty Ltd, to develop and market this technology, offering a better coating solution than those currently available. As the technology develops, Mr Harvey expects that many more applications will emerge, including: enhancing food production by improving the function of greenhouses; scratch-proofing plastics; and improving the performance of high-rise building windows.

“One day soon we will see XeroCoat on products ranging from spectacles, swim and ski goggles to car windscreens and even bathroom mirrors. We are taking nanotechnology out of the lab and putting it in the bathroom,” Mr Harvey said.

Fresh Science is on hold for 2022. We will be back in 2023.

Fresh Science is on hold for 2022. We will be back in 2023.