Airlines and their passengers may both breathe a little easier thanks to a Sydney scientist’s discovery of how to increase cabin airflow without increasing cost.

Chaofan Wu, a PhD student at the University of NSW, has developed a ventilation system that improves airflow in airplane cabins by 10 per cent without consuming more fuel and creating a larger carbon footprint.

“We often hear people complaining about the ventilation during the flight; however, ventilation in the air is extremely expensive because the fresh air is taken from the engine and consumes the airplane’s thrust,” says Chaofan.

“The results of our ventilation system are encouraging as it shows the promise to provide passengers fresher air with no extra cost of engine thrust, which means fuels,” he says.

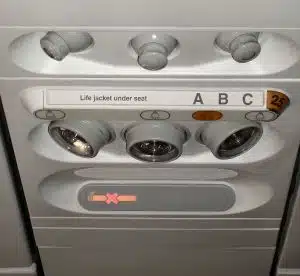

During his research, Chaofan discovered that fresh air travelled along the ceiling and the side of the cabin before coming to the passengers, in traditional airflow delivery systems.

“If the ventilation air could be smarter and go straight to the passengers, the air freshness would be greatly enhanced,” he says.

With the help of colleagues, he developed airflow small devices that could be attached to the inlets on a plane’s ventilation system, creating a more direct trajectory of fresh air to passengers.

Chaofan says his system is compact, inexpensive to build and could be easily integrated with an existing plane ventilation system.

Fresh Science is on hold for 2022. We will be back in 2023.

Fresh Science is on hold for 2022. We will be back in 2023.