Previously unknown species of naturally-occurring bacteria have the potential to save the alumina and aluminium industries millions of dollars while helping to reduce their impact on the environment, microbiologist Naomi McSweeney has found in a collaborative project between Alcoa of Australia, CSIRO and the University of Western Australia.

The bacteria can successfully break down and remove sodium oxalate, an organic impurity produced during the refining of low-grade bauxite into alumina. The work is being presented for the first time in public through Fresh Science, a national competition for early-career scientists. Naomi was one of 16 winners from across Australia.

At a typical refinery, sodium oxalate forms by the tonne during the production of alumina. It can affect the colour and the quality of the final product.

“Oxalate can be removed by combustion, but this process releases excess carbon dioxide”, Naomi says. The impurity may also be stored but this represents a major cost to refineries so treatment is a preferred option.

Alcoa of Australia has designed and installed an innovative large-scale bioreactor which has the capability to remove about 40 tonnes a day of sodium oxalate produced at its Kwinana refinery south of Perth in Western Australia.

“Using bacteria to break down and remove oxalate is a better, more sustainable alternative.” The bacterial process breaks down the sodium oxalate and produces significantly less carbon dioxide whilst avoiding the need to store the impurity.

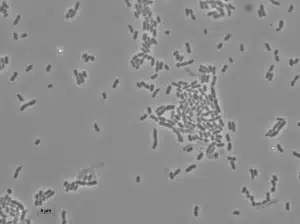

Naomi has worked with researchers from Alcoa’s global Technology Delivery Group and the CSIRO’s Light Metals Flagship to identify the main bacteria involved in degrading the oxalate within the bioreactor. They used DNA fingerprinting techniques to pick out the key players. What they found was a potentially new genus of Proteobacteria and a new species of the known genus Halomonas which are able to use the carbon in the oxalate to grow.

“Oxalates, and bacteria that feed on them, are common in nature –for example in our food, in our guts and in the root systems of plants such as rhubarb,” says Naomi. “However, these oxalate-degrading microorganisms were not the ones we found in the bioreactor.” The bacteria doing most of the work in the bioreactor have never been found before.

To enhance the efficiency of the bio-removal process, the researchers are now determining the best conditions for growing these bacteria. Alcoa is seeking to apply the process to other refineries around the world, and hopes it will be able to use it to treat previously stockpiled oxalate.

Naomi McSweeney is one of 16 early-career scientists presenting their research to the public for the first time thanks to Fresh Science, a national program sponsored by the Australian Government. Her challenges included presenting her discoveries in verse at a Melbourne pub.

- For interviews, contact Naomi McSweeney at Naomi.McSweeney@csiro.au

- For Fresh Science, contact Sarah Brooker on 0413 332 489 or Niall Byrne on 0417 131 977 or niall@freshscience.org

- For Alcoa of Australia, contact Sarah Tempest 9316 5462 or sarah.tempest@alcoa.com.au

- For CSIRO Light Metals Flagship, contact Nola Wilkinson on 03 9545 8744 or Nola.Wilkinson@csiro.au

- For the University of Western Australia, contact Janine MacDonald on 08 6488 5563 or Janine.MacDonald@uwa.edu.au

Other images

Fresh Science is on hold for 2022. We will be back in 2023.

Fresh Science is on hold for 2022. We will be back in 2023.