Using combinations of materials to make cars lighter and reduce their carbon footprint during use might be shifting the environmental burden to the recycling stage of the vehicle, according to research from the Australian National University (ANU).

“Previous work has looked at how the multi-material combination can reduce the vehicle’s carbon footprint during its use. So, I investigated how the changing vehicle designs and manufacturing techniques impact the recycling process once the vehicle is discarded,” says Dr Vi Kie Soo, a life-cycle engineer from the Research School of Engineering at ANU who has led the work.

“I found that as cars become lighter through the combination of different materials, there is a shift to the increasing use of certain joining processes such as screwing, riveting, and gluing.”

Car doors made in 1980s, 1990s, and 2010s were recycled using current shredder-based practices, in a trial conducted with local recyclers.

Newer car doors manufactured in the 2010s were less recyclable than the doors made in 1980s and 1990s, Vi found.

“This is largely caused by using screws to combine different materials that cannot be separated easily,” Vi says.

Currently around 70 million vehicles are produced around the world every year and reach their end-of-life after about 12 years.

Vi hopes her work will assist vehicle manufacturers to design cars that are not only lightweight but also highly recyclable, as well as encouraging policy makers to set stricter vehicle recycling targets.

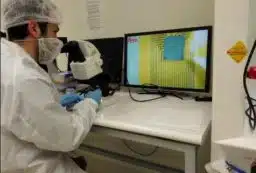

Banner image: Vi has investigated the recycling impact of changing car door materials. Credit: ANU

Fresh Science is on hold for 2022. We will be back in 2023.

Fresh Science is on hold for 2022. We will be back in 2023.