Drills, knives and blades that can last 100 times longer than conventional steel could save manufacturing industries and companies millions of dollars lost each year from broken or blunt tools.

This is the potential of a unique carbon coating developed by a team of Sydney and Melbourne scientists.

The inspiration for the new carbon coating came from sea shells, according to University of Sydney researcher, Mr Peter Ha.

Mr Ha developed a unique coating for cutting tools that is made up of layers of carbon put together in much the same way that layers of carbon are laid down when marine organisms form sea shells.

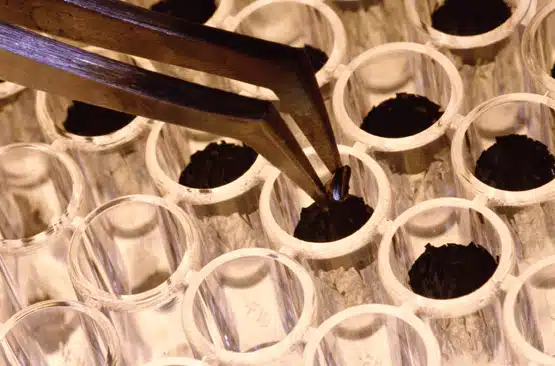

He tested the new coating on drill bits and compared them with steel drills and those coated with titanium nitride (TiN), which lasts about 10 times longer than an ordinary steel drill.

“The drills with the new coating lasted 100 times as long as steel drills, and 10 times longer than the titanium coated drills,” Mr Ha said.

“The special multi-layered carbon structure reduced the friction created during drilling and was able to bounce back into shape if it was indented or distorted in any way.

“This elastic ability makes the coated tools super tough.”

Mr Ha also found that the heat produced during drilling, even without using a lubricant, is much less than for standard coated drills as a result of the greatly reduced friction.

“The new coating produced tools of diamond-like quality that are cheaper to manufacture than diamond drills,” he said. “Imagine a knife, a drill or a blade that stay sharp for its entire life time.”

Coated drills have been tested at the Sutton Tools Company in Melbourne where the drills lasted so long that they ran out of testing material to keeping testing the drills with.

“This method can transform ordinary tools into very durable tools that have the ability to last and last ‘almost’ forever.” said Mr Ha

On Tuesday and Wednesday Peter will be presenting his work to the public at the Great Australian Science Show at the Melbourne Museum along with 15 other Fresh Scientists selected from over 100 nominations.

Peter Ha

PhD (Research) Student Applied and Plasma Physics. University of Sydney

Cutting Tools That Last & Last forever!!!

Multilayer of Carbon Coated On Tools For Industrial Applications

Imagine a knife, a drill, a blade that stay sharp for its life time. For the past, diamond is known for its toughness but it is also known for its price. We can deposit diamond like carbon (DLC) films on tools by a process of Plasma Immersion Ion Implantation (PIII), the results shows tools of diamond like quality and save money.

Project description

The project is part of Australian Research Council with linkage grant with Sutton Tools in Melbourne. Our aim is to bring ordinary tools up to the level of diamond tools by depositing a layer of diamond like carbon. Carbon is a basic substance of all livings, however, diamond is another form of carbon and it is best known for its hardness but expensive. We created a multilayered structure of carbon films to increase hardness and elastic modulus to match our tools to tools of diamond like quality. Our study shows that multilayered structure enhance affects wear performance and improve tool life time.

The key properties of carbon multilayered coating to give it a performance edge are the low friction and its ability to recover elastically after being indented or distorted. The ability to recover or to restructure itself to its original form lead to ‘super tough’ and a superior quality that expand tool life time. The precision of our indentation and elasticity test were measured up to manometer and as to real life as possible.

Our investigations were based on the ‘thought’ of the structure of sea shells and elasticity of rubber bands. We combined our thoughts and years of thin film coating experiences to produce a method that can transform ordinary tools to a super-tough-tool that has the ability to last and last forever. Hence, we can produce diamond like quality tools at a cheaper price.

Personal details

Qualifications: Master of Science at Macquarie University, 2001; Bachelor of Technology (Opto-Electronics), Centre for Lasers and Applications, Macquarie University, 1999; Certificate IV Management and Team Leadership, Granville Technical College. 1999.

Fresh Science is on hold for 2022. We will be back in 2023.

Fresh Science is on hold for 2022. We will be back in 2023.